Controls and connectivity

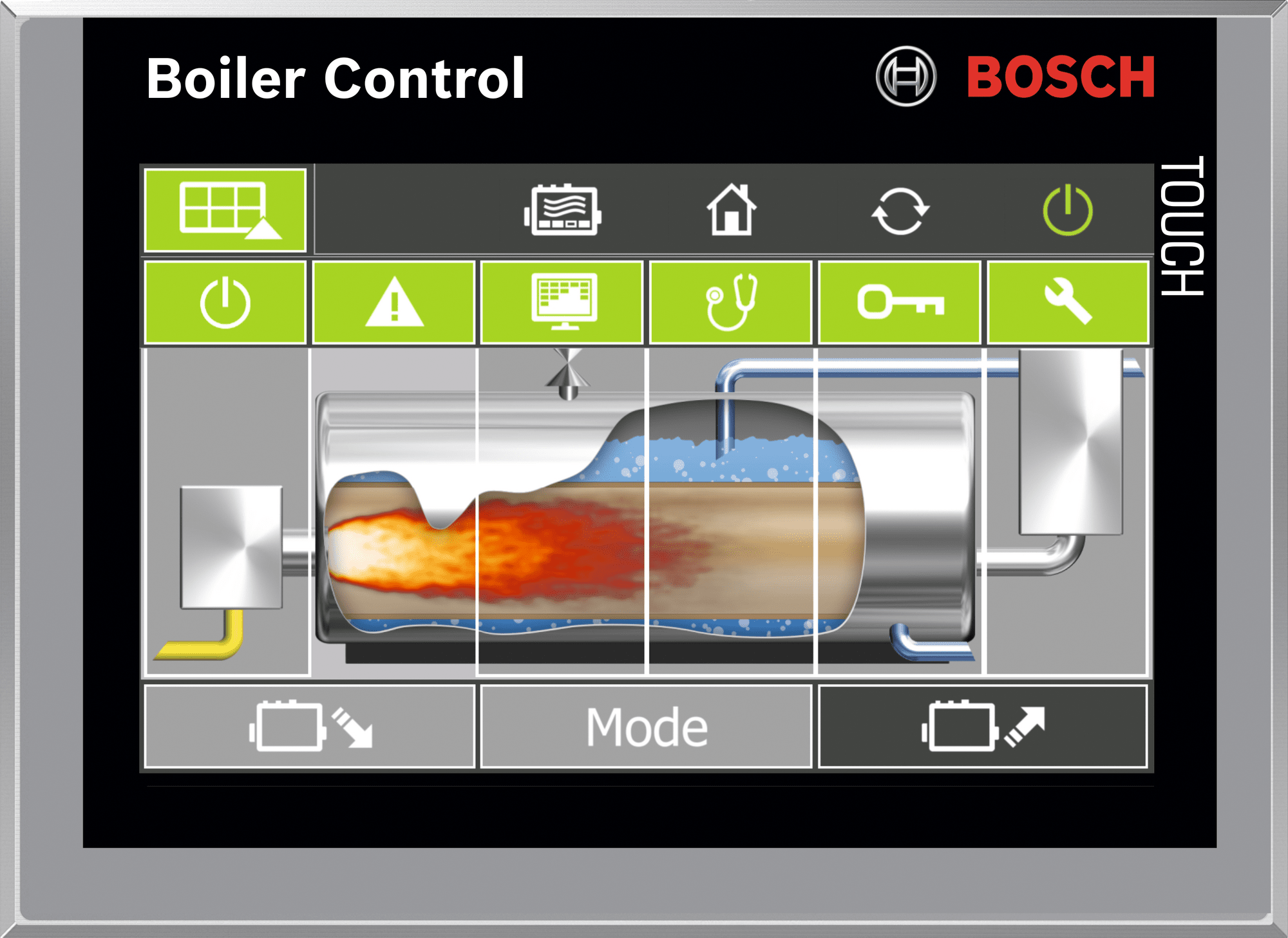

Boiler control BCO

The intuitive boiler control on SPC basis offers very high transparency of operating data for optimum boiler operation.

- Project-specific control system for optimum control of steam or hot water boilers

- Maximum supply and operating reliability thanks to integrated monitoring and protection functions

- Condition monitoring for consistently high system efficiency and availability of steam, hot water and heating boiler systems

- Intuitive operation with graphical symbols and state-of-the-art touchscreen displays

- SUC start-up, standby and shutdown system allows fully automatic high pressure steam boiler operation

- Easy connection to higher-level visualisation and control systems as well as remote access via MEC Remote

Benefits

Overview

- The BCO boiler control comes with all necessary functions for operating steam and hot water boilers according to specialised requirements. Extensive information regarding operating states, operating data and measured values can be viewed on its touchscreen display. Diverse system data are analysed, evaluated and transparently displayed via a traffic light model using the "Condition Monitoring basic" integrated software. Operating characteristics that could lead to a drop in efficiency, increased wear or unplanned stoppages can be determined at an early stage and thereby avoided. A consistently high efficiency and availability of the boiler systems is achieved. The diagnostics function, which is included as standard, supports the boiler operating company or the service technician in quickly localising and rectifying irregularities in operation. This results in a further increase in transparency and operating safety.

- The SUC automatic start-up, standby and shutdown control is optionally available for high pressure steam boilers via the boiler control BCO. When SUC is used, start-up and shutdown processes are performed fully automatically at the press of a button, or in response to an external request signal. The automatic functions protect the system against unnecessary strain during cold starts, in heat maintenance mode, and in normal operation.

Construction

Programmable control with TFT colour display and touch-sensitive surface. The BCO control is integrated in the boiler control panel.

Equipment level

- Performance regulation

- Level control

- Low-load control

- "Condition Monitoring basic" - proactive condition and efficiency monitoring

- Diagnostics function

- Boiler hours run meter

- Burner hours run meter

- Recording of number of burner starts

- Plain text display of operating signals and fault messages

- Message history

- Intuitive, menu-driven operation via touch-sensitive graphic display

- Display and intermediate storage of all relevant measured values and states

- In addition to the basic functions, further options and functions can be added to the BCO control.

Technical Details and Documents

Controls and connectivity brochure

Compatible products

Need help?