Hot water boiler

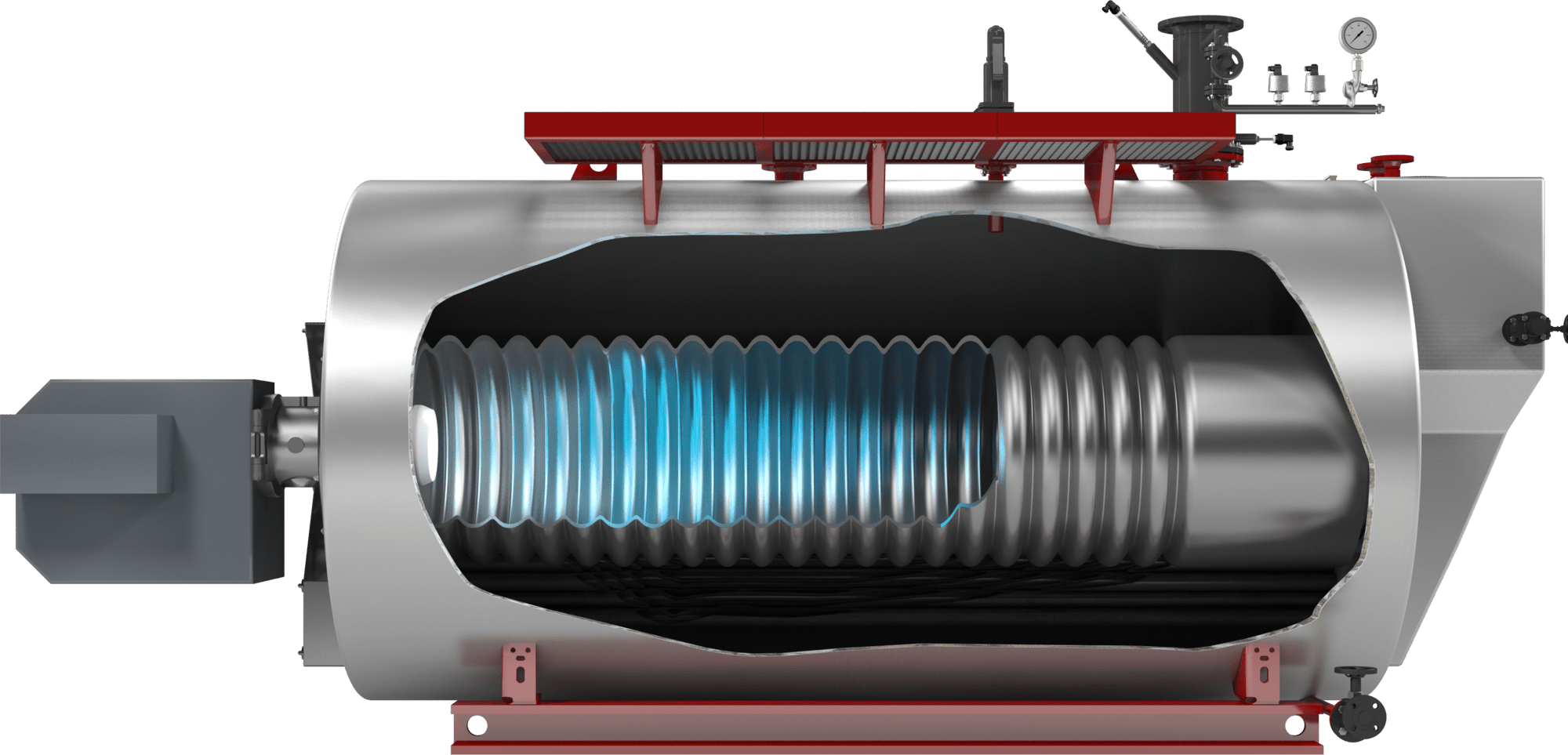

Unimat hot water boiler UT-H

The UT-H is an energy-efficient hot water boiler with outputs from 820 to 18,300 kW at up to 30 bar. Suitable for processes in high temperature and pressure ranges. The boiler can also convert to climate-neutral fuels which makes it a future-proof solution.

- High-pressure hot water boiler from 820 to 18,300 kW with very high efficiency levels

- Versatile operation for the manufacturing industry and district heating grids with temperature levels up to 225 °C

- Customer-specific design and future-proof technology

- User-specific control which offers integration of other control systems and remote monitoring

- Custom designs for heat recovery boilers

- Proven and reliable construction Made in Germany

Benefits

Combined with a flue gas or condensing heat exchanger, the UT-H uses the energy supplied even more efficiently. Potential fuel savings of up to 15%. Additional efficiency components such as combustion optimisation and the high-quality Bosch insulation concept can further increase the efficiency of your boiler system.

The UT-H produces energy-efficient process heat as a single- or multi-boiler system in a high temperature range up to 225 °C at up to 30 bar. The Bosch boiler is particularly well suited to process heating systems in industrial and commercial applications, and to support heating plants.

Bosch builds the UT-H according to project-specific requirements and with individual equipment. The boiler and burner technology are perfectly aligned for environmentally friendly heat production. The technology can be retrofitted to run on climate-neutral fuels such as biogas, bio-oil or green hydrogen at any time.

The UT-H can be easily controlled using the Bosch CWC compact control or BCO boiler control. The pre-configured protocols enable seamless connection to your automation system. The optional MEC Remote access allows you to quickly spot any operational changes.

Bosch offers custom UT-H versions for project-specific requirements, as a heat recovery boiler with firing and fourth pass for the proportional use of waste heat or as a pure heat recovery boiler. Existing waste heat sources, such as from CHP or gas turbines, can be used efficiently and sustainably – saving fuel and reducing emissions.

The applied construction principle used to produce the UT-H offers advantages in terms of service life and operating safety. The arrangement of the flame tube and reversing chamber ensures consistent heating even in cold conditions and reduces stresses in the boiler. The optimised water content enables the UT-H to quickly reach its operating temperature.

Technical Details and Documents

Heat transfer medium

High-pressure hot water

Design

Three-pass flame tube/smoke tube technology

Output

820 to 18.300 kW

Safety pressure

up to 30 bar

Max. temperature

up to 225 °C

Fuel

Gas, oil, bio gas, bio oil, hydrogen